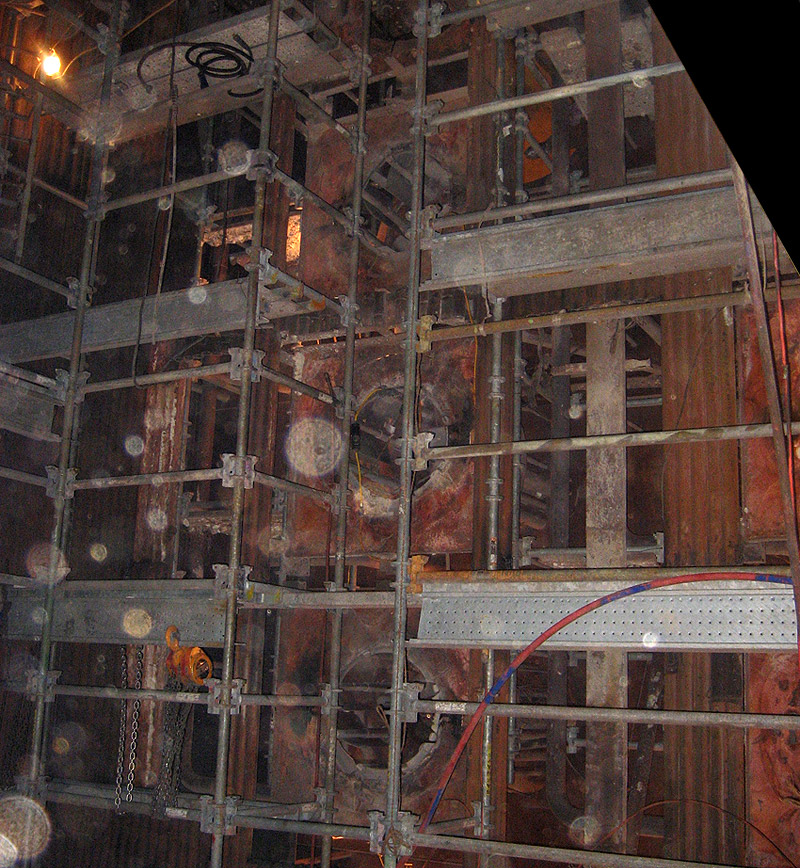

PBS replaced water wall tubes in the burner front, rear, and side walls. Approximately 710 defected water wall tubes were demo and new tubes were installed. PBS was responsible for bending all tubes that were replaced at the burner and over the fire air ports. PBS arranged to have bending of tubes completed by a bending vender. After proper bending was confirmed the tubes were fitted and welded by PBS. Several resections of tubes were completed throughout the boiler; 162 tubes were replaced in the bull nose, 196 tubes were replaced in the north wall (of which 72 were burner cell tubes), and 350 tubes were replaced in the south wall, west wall and east wall. Windows of 10 tubes were cut and replaced at a time until all tubes were completed. Additional boiler repairs were completed. This project required a total of 1,800 field welds. Approximately 20,000 man hours were expended on this project with zero injuries and zero time loss.